Home Compostable Packing

Packing with Paper Film

Tray-Less Upgrade

Low Impact Manufacturing

Recycle, Biodegrade, Compost

We can supply our flowrappers and customer upgrades fully configured for

Home Compostable Packing

A Compatible Machine

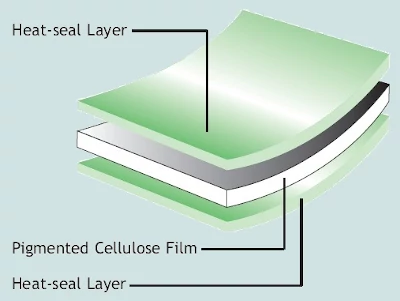

As part of our standard upgrade process we can adapt your flowrapper to operate with renewable and compostable NatureFlexTM films, which are produced from sustainably managed forests and are certified for both home and industrial composting.Environmentally Responsible

This not only properly satisfies the increasing demand for more environmentally responsible packaging but also gives you an obvious marketing opportunity without the huge cost of new machinery. NatureFlexTM films are tailored to provide a range of heat seals and barriers (gas, moisture and mineral oil) and are available in semi-permeable, barrier and metallised for a wide variety of flowrap applications.Working as a Team

Natureflex is produced by Futamura and we work closely with their UK based technical team. Our wide range of flow wrapper makes and models and technical knowledge is the ideal environment for testing new films. As part of the flow wrapper upgrade process we can modify your machine to operate with NatureFlexTM compostable films as well as conventional OPP films and laminates.Genuine Credentials

Packing with Paper Film

Can we use paper ?

What is Park2Nature ?

Park2NatureTM is a laminate of 25g or 40g paper made from pulp, eucalyptus trees and bio-polymer derived from natural resources such as sugarcane, cassava and corn. It is produced from sustainably managed plantations which essentially means that every tree felled is replaced with at least one more. It is ideally suited to dry goods that require a barrier against oxygen and moisture and it has a natural barrier to aroma, oils and grease.What happens to it ?

How well does it work ?

Our own team of experts, working with Parkside's UK based organisation, have tested and evaluated their Park2NatureTM film on a selection of our modified flowrappers. Normally we don't expect much from paper films but, without question, Park2NatureTM produced packs which ran seamlessly through our modified flowrappers and produced finished packs with strength comparable to conventional plastic packaging.Tray-Less Flowrapper Upgrade

With some products, removing the tray and directly handling difficult unstable products can be a challenge. However, we have a wealth of engineering and practical experience backed by highly qualified academic specialists who can help you achieve high speed tray-less packing.

In some cases card can replace the plastic tray and we can supply automatic card feeders and folders. We can add self powered top brush and paddle systems, modify or build new infeeds to carry spherical, difficult or multi-pack products. We can design bespoke specialist feeding systems. Take a look at the video to see some examples of how we can stretch the capabilities of standard flowrappers.

Some applications require the use of more specialist box motion, long dwell and inverted machines which can be very expensive, so the savings we offer are even more significant.

One of our remanufactured machines, or upgrading your own, allows you to meet the increasingly 'green' demands of your customers as well as meet inevitable future legislation.

Low Impact Re-Manufacturing

Manufacturing any new machinery uses energy, generates greenhouse gases and uses valuable natural resources way beyond what most people imagine. Making a new flowrapper can actually create more environmental damage than a lifetime of use.

So a used machine really does help save the planet. But we don't simply rebuild old machines - we remanufacture 'better than new' flow wrappers using parts from old ones. The frame, body and covers don't wear out. Worn bearings are easily replaced with new ones. And the internals are replaced by a class-leading latest generation efficient multi-motor system.

So you get a 'better than new' machine without the price tag or environmental damage of a new one.

Recyclable, Biodegradable, Compostable ?

Should I use recylable, biodegradeable or compostable film? In truth it's a very complex subject that's driven by marketing, social perception, global politics and cost as much as it is by science. Here's our brief straight forward explanation:

Recyclable

film theoretically includes most plastics. As a wrapping material it's near perfect except for our careless disregard for how we dispose of it after use. There is a limit to the number of times it can be recyled and it requires an extensive collection, sorting and processing infrastructure which is very difficut to impliment effectively. It's also heavily compromised by multi-material laminates and barrier layers which are used to modify its properties and extend shelf life. There are currently no globally recognised standards covering the manufacture of recylable films or the recyling process.Biodegradeable is quite a vague term but generally relates to plastic film with special additives designed to make it break down under certain microbiological conditions. However there is no well defined standard stating, for instance, how long it takes or what it actually breaks down into. Critically, it's still made from the same core materials as petroleum based film and can simply disintegrate into equally damaging microplastic particles.

Compostable films are produced from naturally occuring materials and decompose fully without any toxic residue and can actually provide regenarative nutriants. Some require a controlled industrial process while others are certified as Home Compostable and both must meet specific EN certification standards. However, because it currently represents a very small proportion of total packaging material, together with a lack of industrial processing, means it is often incinerated along with residual waste.

Simply throwing new technology films at existing horizontal flowrappers seldom works. It takes expertise and knowledge to build and suitably prepare equipment for these new environmentally friendly materials. Some of the world's leading film manufacturers work closely with us, testing their products on our wide range of makes and models. We can test any new film you are thinking of using and work with you on preparing your own upgraded or remanufactured flowrapper.

Simply throwing new technology films at existing horizontal flowrappers seldom works. It takes expertise and knowledge to build and suitably prepare equipment for these new environmentally friendly materials. Some of the world's leading film manufacturers work closely with us, testing their products on our wide range of makes and models. We can test any new film you are thinking of using and work with you on preparing your own upgraded or remanufactured flowrapper.

Ready for Change

As momentum builds, international government legislation will undoubtedly become increasingly demanding. The UK's levy on plastic shopping bags and the ban by the Chinese government on imports of plastic waste are just the start. We might soon see prominent "NOT RECYCLABLE" as mandatory marking on films and taxes or levies designed to penalise producers using plastic or non-recyable films or excessive packaging. Not to mention the pollution and environmental damage caused by scrapping your old machine. As someone who has to wrap, you are bound to be concerned. So talk to us - we can help with these new challenges and still keep your budget under control.