The Best of British

Standard Flow Wrappers

Top-Seal Flow Wrappers

Integrated On-Pack Printers

Automatic Product Loaders

The Best of British

British Built for British Companies

Most flow wrappers sold in the UK are imported. Our flow wrappers are built in Britain and are specifically matched to UK requirements with a unique blend of quality, performance, versatility and competitive price.

Most flow wrappers sold in the UK are imported. Our flow wrappers are built in Britain and are specifically matched to UK requirements with a unique blend of quality, performance, versatility and competitive price.Twenty Five Years of British Quality

Built by experienced engineers and supported by master degree level designers plus twenty five years of experience. Our manufactured components are made in-house or by trusted local specialists and the software in our class leading control system is programmed and supported by our own in-house software engineers.Series 1000 - Standard Flow Wrapper

The series 1000 is a rugged industrial grade flow wrapper designed and manufactured in the UK. Capable of packing a particularly wide range of bakery, confectionery, medical, snack and non-food items. Both individual and multi-pack products in plastic and new non-plastic materials. It's a fully featured latest generation machine which is particularly easy to operate, hygienic, low maintenance and competitively priced.

Standard Specification

Stainless steel body and contact areas

Tool-Less Easy-Clean loading conveyor

Simple operation and 50 automatic product memories

Printed film capability, high accuracy, instant lock-in

No-Product-No-Bag pack on demand

Automatic bad product jam recovery

Fixed or fully adjustable bakery type fold-box

Expert installation, training and support

Two year extended warranty

Options

Integrated Thermal Transfer Printer

Cut-away jaws for extra high products

Multiple jaws for high speed or small products

Automatic Euro-slot for hanging hook display

Custom Infeeds with loading tray, product carriers, etc

Knife-edge discharge for small products

'SimpleFeed' automatic in-line low cost loader

'SlipFeed' automatic in-line high speed loader

Robot loader interface (Blueprint, PWR, Schubert, etc)

Series 2000 - Top-Seal Flow Wrapper

The Series 2000 is specifically designed for difficult to handle single and multiple products. The products are placed on a moving conveyor belt and are carried and supported all the way through the flow wrapper. It is ideal for random shaped, sticky, easily damaged or a collection of different sized multiple products.

Standard Specification

Top-Seal 'inverted' model for difficult products

Stainless steel high-hygiene construction

Tool-Less input belt removal and cleaning

Simple operation and 50 automatic product memories

Printed film capability, high accuracy, instant lock-in

Automatic bad product jam recovery

Expert installation, training and support

Two year extended warranty

Options

Integrated Thermal Transfer Printers

Cut-away jaws for extra high products

Multiple jaws for high speed small product

Automatic Euro-slot for hanging hook display

Waterproof wash-down input conveyor

Upstream synchronisation trigger for automatic loading

On-Pack Printers

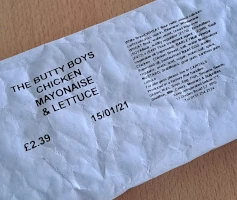

We can supply a range of integrated Thermal Transfer Printers for fully automatic, low cost per pack, printing with any of our flow wrappers. Capable of printing everything from a simple sell-by date, through complex ingredient and regulatory information, batch codes, QR codes and bar codes, all the way up to large complex graphics covering almost the entire pack.

Zodiac Falcon

We have partnered with Clearmark to offer their Zodiac range of printers pre-installed on any of our flow wrappers. The Zodiac range is the leading Thermal Transfer Printer on the market and has an excellent reputation for reliability, ease of use and efficiency. The 54mm version is our most popular model and boasts integrated print checking with its own internal camera and an all electronic design with no compressed air requirement.

Specification and Features

Maximum print width 32mm, 54mm or 107mm

Maximum print length 200mm

No compressed air requirement

No minimum speed, no missing prints

Print position controlled from flow wrapper screen

Real-time self checking for bad prints

1,200 metre extra long ribbon capability

Simple fast ribbon change over

Comprehensive image design software

Merlin D03S

The Merlin DO3S is a basic Thermal Transfer Printer which provides a quality solution at a low price. It is ideal for basic applications where budget is a primary concern. It includes a touch screen controller and simple graphic design software.

Specification and Features

Maximum print width 32mm

Maximum print length 100mm

Low volume compressed air requirement

Print position controlled from flow wrapper screen

500m ribbon capability

Simple fast ribbon change over

Basic image design software

Automatic Product Loaders

SimpleFeed low cost automation

Our new and unique 'SimpleFeed' automatic product loader provides a low cost solution for automating the loading of your flow-wrapper. It gives smaller and lower volume manufacturers a way into the world of automation. It can be added to your existing flow-wrapper as part of a refurbishment and upgrade, or to one of our excellent remanufactured flow-wrappers, or a new flow-wrapper. Save tens of 1,000's on purchase, then tens of 1,000's on labour - every year!

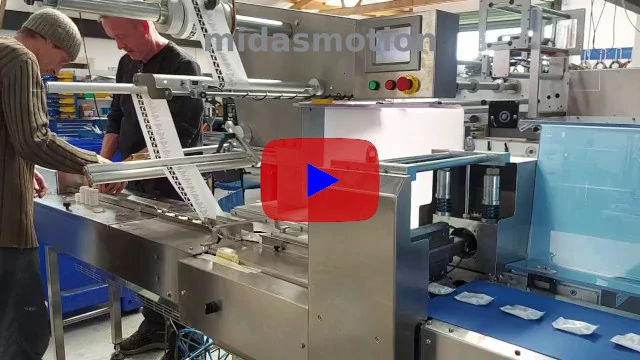

Series 4000 Full Automation

The series 4000 system is a modular comprehensive collection of in-line feeder equipment for automatically loading flow wrappers. The video shows a confectionery packing line that demonstrates everything from standard conveyors, our clever spreading conveyors, reject and divert station, accumulation, and metering into a high speed flow-wrapper. All of it supplied new by midasmotion as a fully integrated automatic high speed packing line based on 4000 series modules.